3D printing and injection molding are two of the most common manufacturing processes for creating plastic parts. Both processes have their own advantages and disadvantages, and the best choice for a particular application will depend on a number of factors.

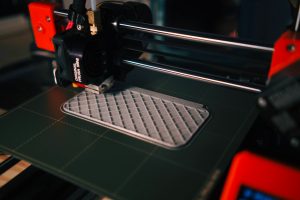

3D Printing

3D printing is an additive manufacturing process that creates objects by building them up layer by layer. This makes it a good choice for creating complex shapes that would be difficult or impossible to produce using traditional manufacturing methods. 3D printing is also a relatively quick and easy process, which makes it a good choice for prototyping and low-volume production.

However, 3D printing is not without its limitations. The quality of the finished parts can vary depending on the type of 3D printer used, and the materials that can be used in 3D printing are limited. Additionally, 3D printing can be a more expensive process than injection molding for high-volume production.

Injection Molding

Injection molding is a subtractive manufacturing process that creates objects by injecting molten plastic into a mold. This makes it a good choice for producing high-quality, consistent parts in large quantities. Injection molding is also a relatively cost-effective process for high-volume production.

However, injection molding is not as versatile as 3D printing. It is not possible to create complex shapes using injection molding, and the process can be time-consuming for prototyping and low-volume production.

Comparison of 3D Printing and Injection Molding

| Feature | 3D Printing | Injection Molding |

|---|---|---|

| Process | Additive | Subtractive |

| Versatility | High | Low |

| Quality | Variable | High |

| Cost | Low (prototype) | High (high-volume) |

| Speed | Fast (prototype) | Slow (high-volume) |

| Materials | Limited | Wide range |

| Applications | Prototyping, low-volume production | High-volume production |

Which Process is Right for You?

The best way to decide which process is right for you is to consider your specific needs and requirements. If you need to create complex shapes or prototypes, 3D printing is a good option. If you need to produce high-quality, consistent parts in large quantities, injection molding is a better choice.

In general, 3D printing is a good choice for small-scale production, while injection molding is a good choice for large-scale production. However, there are always exceptions to the rule, so it is important to carefully consider your specific needs before making a decision.