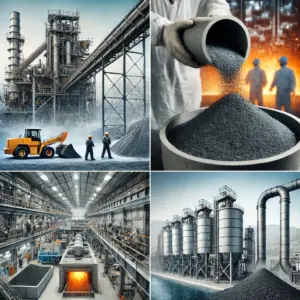

Coal dust often conjures images of miners emerging from the earth blanketed in a fine, black soot, but this raw material embodies far more than an occupational by-product. As a versatile substance that finds utility across various industries, coal dust is a key component in numerous processes and products. The use of coal dust is widespread, spanning from energy generation to metal production, and even into environmental applications such as water treatment.

The Industrial Relevance of Coal Dust

Coal, as a combustible sedimentary rock, is composed primarily of carbon along with assorted other elements, including hydrogen, sulphur, oxygen, and nitrogen. When ground into a fine powder, coal dust can be utilised in several industrial processes that necessitate a readily combustible material with a high surface area. The fine particulate nature of the dust allows for a rapid and complete combustion, making it an ideal candidate for numerous industrial applications.

One of the fundamental uses of coal dust is in the production of energy. Power stations harness the combustion properties of coal to generate electricity. The high surface area to volume ratio of finely milled coal dust enables it to ignite and burn more efficiently than larger chunks of coal. This efficiency not only optimises fuel usage but also helps in reducing emissions produced by power plants.

Coal Dust in Metallurgical Processes

In metallurgy, coal dust plays a pivotal role during the process of iron and steel manufacturing. Known as a reducing agent, it contributes to the conversion of iron ore into iron in blast furnaces. The carbon-rich composition of coal dust helps in reducing the oxides present in the ore, which aids in separating the metal from its raw form.

Beyond energy generation and metallurgy, coal dust shows versatility in agriculture too. It is sometimes used to improve soil properties, helping to increase the carbon content which can be beneficial for plant growth. While not as widespread as other applications, this secondary use of coal dust demonstrates its multifunctionality.

Coal Dust within Environmental Solutions

The environmental sector finds a surprising ally in coal dust, notably in the form of activated carbon. This material, processed to have small, low-volume pores that increase the surface area available for adsorption or chemical reactions, is essential in purifying and treating water and air. It effectively removes contaminants through a process called adsorption, where pollutant molecules adhere to the surface of the activated carbon particles. This trait makes activated carbon invaluable in mitigating environmental pollution.

Coal dust can undergo an activation process where it is heated to high temperatures in the presence of an oxidising gas or chemical agent. This process clears out the internal structure of the carbon, vastly expanding its absorptive surface area. The increased porosity of activated carbon allows for the efficient trapping of chemical impurities, hence its extensive use in water and air purification systems.

James Cumming and the Evolution of Coal Dust Utilisation

Understanding the impact of coal dust on the industrial landscape James Cumming, a key Australian company, has been at the forefront of supplying high-quality coal dust for various applications. By ensuring that the coal dust they provide meets stringent quality standards, they cater to industries requiring this versatile material for their operations.

James Cumming has developed and honed the processing and handling of coal dust, ensuring that it can be delivered in a form that maximises its performance for a myriad of uses. Their commitment to quality underlines the importance of this material’s role in contemporary industrial and environmental processes.

Safety and Environmental Considerations

While the use of coal dust is widespread, it is not without its challenges. One of the primary concerns associated with coal dust is the potential health risks for workers exposed to it. Prolonged inhalation of coal dust can lead to respiratory issues, making it essential for industries to uphold strict safety standards and implement robust dust management systems.

Additionally, the environmental implications of coal dust emission necessitate responsible handling and utilisation. Companies like James Cumming are crucial in ensuring that coal dust is processed and supplied with a commitment to safety and environmental stewardship. It is through the refinement of practices and technologies that coal dust continues to be handled in a manner that minimises its ecological footprint.

Conclusion

Coal dust might appear to be a humble by-product of coal mining, but its uses are both expansive and essential. It is a principal element in various major industries, contributing to processes that span from energy production to heavy metal manufacturing and environmental remediation. Not merely confined to its traditional roles, coal dust’s role as a source of activated carbon signifies its importance in modern-day pollution control methods.

The comprehensive understanding of James Cumming in the field of coal dust production and its multi-industry applications is a testament to the material’s adaptability and significance. As the world progresses towards efficiency and sustainability, coal dust will undoubtedly remain an invaluable component within the industrial fabric. It is this versatility that cements coal dust’s place as an essential, albeit unlikely, ally across numerous sectors.