Key Takeaways

- 3D printing is revolutionizing various industries by providing cost-effective and time-efficient solutions.

- It offers unparalleled customizability in manufacturing, opening new avenues for innovation.

- Several sectors, including healthcare, aerospace, and fashion, are leveraging the benefits of 3D printing.

- Environmental sustainability can be enhanced by adopting 3D printing technologies.

Table of Contents

- Understanding 3D Printing

- Applications and Benefits

- Impact on Healthcare

- Aerospace Innovations

- Fashion and Consumer Goods

- Environmental Sustainability

- Future of 3D Printing

Understanding 3D Printing

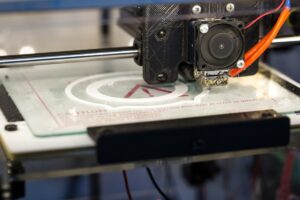

3D printing, or additive manufacturing, is a cutting-edge technology that fabricates three-dimensional objects from a digital file. Unlike traditional subtractive manufacturing, which typically involves removing material from a larger piece, this process builds objects layer by layer. In contrast, 3D printing creates objects by adding material layer by layer. This method dramatically reduces waste and provides designers unparalleled flexibility in producing complex structures. For more on 3D printing’s versatility, click here to explore various applications.

Over the years, 3D printing has made waves across numerous industries, presenting innovative solutions to old challenges. Its applications are vast, from creating bespoke medical devices to prototyping architectural models. As the technology matures, its potential for reshaping industries becomes ever more palpable. By streamlining production processes and enabling on-demand manufacturing, 3D printing minimizes the need for inventory and reduces lead times, offering efficiency that conventional methods cannot match.

Applications and Benefits

The reach of 3D printing spans from industrial to personal use. Industries, from manufacturing to education, benefit from its ability to craft intricate designs quickly and cost-effectively. This versatile technology continues to push boundaries, enabling innovations that seemed impossible a decade ago. A fascinating read on the wide-ranging applications of this technology illustrates just how integral 3D printing has become in our everyday lives.

One of the standout benefits of 3D printing is its capability to produce personalized items. Unlike mass production, which churns out identical items, 3D printing can cater to individual needs, crafting everything from custom toys to tailored footwear. This level of customization is spearheading a new era of consumer experience, aligning products with personal preferences and ergonomics. Additionally, businesses can test prototypes and iterate designs more efficiently, increasing their ability to innovate while staying adaptable to market demands.

Impact on Healthcare

The healthcare sector has experienced a remarkable transformation by integrating 3D printing technology. This advancement allows for creating personalized solutions, such as prosthetics and dental implants, tailored to each individual’s unique physical needs. This custom approach reduces the risk of rejection and improves patient outcomes by ensuring comfort and functionality.

Additionally, 3D printing allows for the rapid production of surgical instruments and models that assist in planning and executing complex surgeries. By providing solutions that cater to individual needs, 3D printing revolutionizes healthcare practices, improves patient care, and helps to reduce costs.

In addition to personalized medical devices, 3D printing is used to develop intricate anatomical models for educational purposes. These models help train medical professionals by providing realistic simulations of human anatomy, thereby improving the quality of medical education and training worldwide.

Aerospace Innovations

In the aerospace industry, the adoption of 3D printing is driven by its ability to produce lightweight, durable components that enhance aircraft performance and safety. These components contribute to substantial fuel savings, which is crucial in an industry where efficiency is paramount. As aerospace companies strive to meet global demands for sustainability, the ongoing integration of additive manufacturing technologies becomes vital in reducing operational costs and environmental impact.

The ability to produce complex geometries that are otherwise impossible or too costly with traditional methods offers a significant competitive advantage. Components such as turbine blades and intricate assembly parts can now be crafted with precision and efficiency, pushing the boundaries of design and functionality.

Fashion and Consumer Goods

The fashion world is embracing 3D printing for its potential to revolutionize design and production processes. Fashion designers are using this technology to create intricate patterns and structures that were once unthinkable within the constraints of conventional techniques. 3D printing allows for rapid prototyping and iteration, allowing designers to fine-tune their creations easily.

Similarly, in consumer goods, companies leverage 3D printing to offer customers personalized products, thus creating distinctive and memorable experiences. From custom phone cases to bespoke home decor, the move towards manufacturing on demand is creating new opportunities for innovation and consumer engagement. This shift enhances product personalization, minimizes waste, and reduces inventory requirements.

Environmental Sustainability

Environmental considerations are increasingly central to business decisions, and 3D printing is emerging as a key player in the drive toward sustainability. 3D printing offers a greener alternative to traditional methods that often produce significant byproducts by minimizing waste and optimizing material usage during manufacturing.

Moreover, producing goods locally helps reduce the carbon footprint associated with transportation, as products can be made closer to the point of consumption. Recent scientific research has highlighted the positive environmental impact of adopting these technologies, showcasing their potential as sustainable solutions for future manufacturing endeavors. As industries become more eco-conscious, the adoption of 3D printing technologies is expected to grow, fostering further advancements in sustainability.

Future of 3D Printing

As we gaze toward the future, the evolution of 3D printing appears boundless. Developing new materials and enhanced printing techniques promises to expand its applications across various industries. Continuous research in material science leads to the discovery of more substantial, versatile materials, such as metals and composites, designed for particular applications.

As industries continue to explore how best to incorporate this technology into their production lines, 3D printing stands poised to redefine manufacturing landscapes worldwide. With its growing influence, the future of 3D printing is not just a question of possibility but of significant transformative potential. The journey of 3D printing is, in many ways, just beginning, and its evolution will undoubtedly continue to unfold, pushing the boundaries of feasible and enhancing the intersection between technology, innovation, and everyday life.